Welcome to Arttangent (Shanghai)

23+ Years OEM/ODM Manufacturer

Casting/Injection Molding, CNC, Sheet metal & 3D Printing

- OEM/ODM

- ±0.01mm Precision in Plastics

- Expertise in Plastic Injection Mold design and making ,injection molding service,decoration and assembly service

They Trust Us

Product Application Scene

Who We Are

Why Choose For Your Need

Arttangent (Shanghai) Technology Co., Ltd. established in 2001, is a company with a workforce of 100 employees. We hold certifications in ISO 9001:2008 and IATF 16949, demonstrating our commitment to quality and excellence. Our core competencies lie in the design and manufacturing of injection molds, plastic components, as well as services encompassing painting, printing, welding, hot stamping, laser etching, and assembly.

With a dedicated and skilled team, we are committed to delivering top-notch products and services. Our guiding principles are rooted in professionalism, integrity, and innovation. We are steadfast in our pursuit of process control, maintaining stable quality, and ensuring customer satisfaction.

Our overarching goal is continuous improvement, both in meeting our customers’ needs and contributing to society as a whole. We are unwavering in our commitment to upholding the highest standards of excellence.

Out Advantage

We offer end-to-end services, from mold design and manufacturing to injection molding and product assembly, providing a one-stop solution for clients.

Guarantee ±0.01mm torelance: We are equipped with high-precision mold manufacturing equipment, ensuring top-notch production capabilities.

We follow ISO9001:2008 quality management standards, guaranteeing the quality of its products and services.

We offer extensive after-sales services, including mold preservation and repair, plus complete product support. Trust in our commitment to your long-term success and peace of mind.

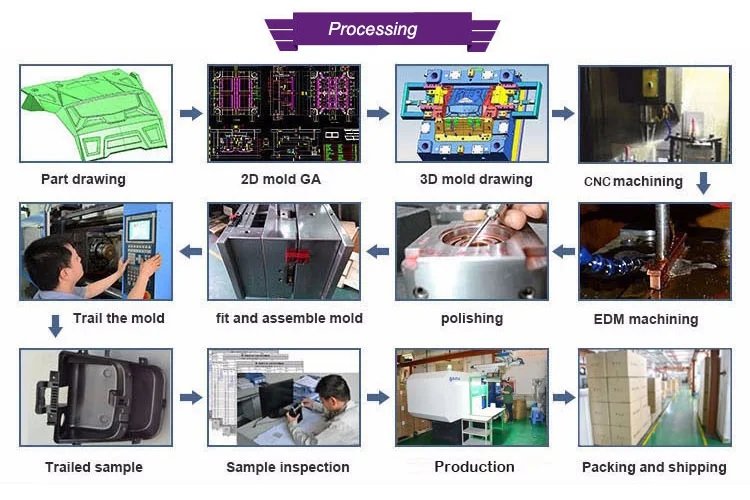

Moulding Processing

Drawing Review—-Material Preparation—-Processing—-Mould Frame Processing—-Core Processing—-Electrode Processing—-Mould Parts Processing—-Inspection—-Assembly—-Flying Mould—-Trial Mould—-Production

At Arttangent Technology, our mold production process exemplifies professionalism and precision. Initially, precise design is conducted through UG/CAD/CAM/CAE systems, ensuring optimal detail and functionality for each mold. Next, efficient machining is executed at our CNC machining center, meticulously crafting each component. Subsequently, advanced testing equipment is utilized for stringent quality checks, guaranteeing each product meets international standards. Finally, advanced injection molding techniques are employed for precise forming, ensuring product quality and performance. Every step in our process is dedicated to creating top-quality molds to meet diverse industry needs.”

Production Department

Certificate

Plastic Product Processing Factory

We are an automotive interior accessories, electronic appliances, instrumentation, fitness medical equipment, industrial and daily life related plastic products open mold injection molding processing plant, professional injection mold design and development and manufacturing, injection molding plastic products plastic parts, plastic injection molding products and injection molding products, as well as the appearance of more post-processing, and assembly of plastic injection molding products in one of the professional modernization of the company.

Kuixing's Value

There is a great man in the East called Confucius, and Confucius is not only known as a saint, but also known as "Arttangent"- one of the 28 hosts in the sky, i.e., the four stars (or the first one) of the Big Dipper's seven-star spoons. We believe that with Arttangent the industry persistent 10 years of accumulated production technology experience and customer contacts, as well as Quixing's own unique management concepts and Arttangent's open-minded and advancing with the times of the times, we are now certainly not the best, nor the largest, but we are working hard and progress, Arttangent invites all the world's merchants, and happy to meet the four sides of the friends. In the future will continue to shine

- Customized strategies tailored to your business needs.

- Ongoing support and assistance post-project completion.

We will prioritize sustainable practices and materials in our manufacturing processes, contributing to a greener and more eco-friendly future while meeting the demands of environmentally conscious consumers.

Our strategic expansion plans will enable us to serve a wider international market, strengthening our position as a preferred partner for businesses seeking precision plastic molding solutions on a global scale.

We will invest in advanced automation and smart manufacturing technologies to enhance efficiency, reduce production costs, and ensure consistent product quality, positioning ourselves as a leader in Industry 4.0 practices.

Future Vision

“Our future vision is to become a global leader in injection molding and plastic manufacturing. We aspire to continuously innovate, expand our capabilities, and set new industry standards. By leveraging cutting-edge technology and sustainable practices, we aim to be at the forefront of providing high-quality plastic products and solutions that meet the evolving needs of our customers worldwide.”