Contents

- Comparing Filament and Resin 3D Printers

- What are Filament 3D Printers

- What are Resin 3D Printers

- Filament vs Resin 3D Printers

- Production Scale

- Costs

- Complexity

- When to Use Filaments 3D Printers?

- When to Use Resin 3D Printers?

- Using 3D Printing in Injection Molding

- Getting Plastic Injection Molds for Your First Project

Comparing Filament and Resin 3D Printers

3D printers are the future of the manufacturing industry, being one of the most disruptive pieces of technology in the last decade. 3D printing boosts production immensely, and it is also a highly scalable solution, which makes it an integral part of the modern supply chain. Naturally, it is also a new frontier in injection molding, and integrating 3D printing in your injection molding process is a great way to not only cut down on costs but also speed up production.

Filaments and resins are two very popular types of materials in 3D printing. Both are different in fundamental ways that can have a huge impact on your entire process, so it is important to choose the right types of 3D printers for your business.

What are Filament 3D Printers

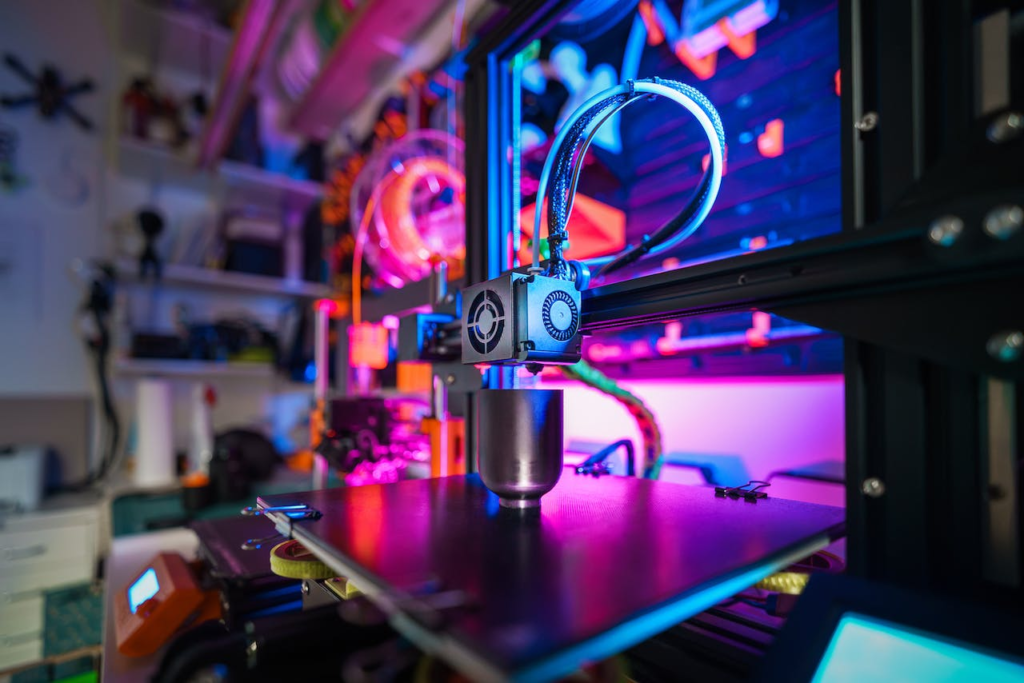

Also called fused deposition modeling 3D printers, filament 3D printers take thermoplastic filaments as feedstock to create models that look exactly like the original design. These filaments are heated and melted inside the machine. Then, the melted material is deposited on the board layer by layer to create the finished product.

This process is widely used across industries, and it is perhaps the most popular method of 3D printing. It is most commonly used to produce larger parts.

What are Resin 3D Printers

Resin 3D printing is also called stereolithography, and it has, surprisingly, been around since at least the 80s. In this process, the engineer would first pour liquid resin into a tank. A source of precise light, which is often laser or DLP, will then shine the light into the liquid resin, slowly solidifying it in a complex photochemical process. As the light slowly cures the resin, the tank will also be slowly lifted up so that the engineer can check in on the progress.

Resin 3D printing is a very complicated process with a lot of moving parts, so it requires specific knowledge as well as more complicated setups. This is the 3D printing method that the automotive industry prefers.

Filament vs Resin 3D Printers

Both filament and resin 3D printers have their ups and downs, and depending on the situation, you might find one choice superior over the other. Let’s take a look at both 3D printing methods from the angles of production scale, costs, and complexity.

Production Scale

In terms of production speed, filament 3D printers should take the cake, as they are uniquely capable of producing large models, making it much easier for you to scale up production. On the other hand, resin 3D printers are more commonly associated with smaller parts, and scaling production will be much harder.

Costs

Again, filament 3D printers are the clear winner here, as they are much cheaper to operate. The average filament 3D printers cost less than resin 3D printers since the technologies involved are simpler. Furthermore, filaments do not cost as much as liquid resin, so you will be able to keep the costs down.

Complexity

In this respect, resin 3D printers will blow your mind away with the complexity of the finished products. Because these printers use light to cure the liquid resin, the accuracy of the process is really impressive, and even small details as well as holes are reflected in the final products. Filament 3D printers are generally used for simple parts only.

When to Use Filaments 3D Printers?

Filament 3D printers are very reliable tools for creating large parts en masse. Parts such as helmets or plastic plates can be produced at a large scale using 3D printers and injection molding, which helps you earn millions of dollars.

Filaments 3D printers also feature a much easier learning curve. Engineers don’t have to spend too much time to get used to these machines, so you can start production right away.

When to Use Resin 3D Printers?

Because resin 3D printers can produce parts with high accuracy and complexities with ease, they are the industry-standard solutions in the automotive industry. Car parts need to be exact, or else accidents may happen. Thus, resin 3D printers can fill in this gap with their amazing complexity. Resin 3D printers are also popular with manufacturers who specialize in airplane parts.

It should be noted that resins 3D printers can be quite hard to learn, so your engineers will need to take some time to learn the materials as well as the process itself.

Using 3D Printing in Injection Molding

Incorporating 3D printing, whether filaments or resins, into your injection molding workflow is a great way to boost your injection molding business. 3D printing is particularly useful for creating the mold, the central heart of any injection molding production plant. Mold design can be a very expensive process, so experts can help you out by 3D-printing plastic injection molds. With these molds, you can build an injection molding production line with ease, enabling you to take on massive bulk orders.

Getting Plastic Injection Molds for Your First Project

If you opt for custom plastic injection molds, we are here to help. Kuixing Shanghai is a team of experts with over 20 years of experience in the industry, and we are capable of producing custom-made plastic injection molds depending on your requirements and needs. Our experts ensure that you will be involved throughout the process to create the perfect plastic injection mold for your needs.

If you need simple plastic injection molds that are proven to bring you plenty of great orders, check out our collections of plastic injection molds!

Filament 3D printers and resin 3D printers are different in many fundamental ways. While filament 3D printers are cheaper and more scalable, resin 3D printers offer much better accuracy and precision in the printing process, which results in better-looking products. However, resin 3D printers are not capable of producing large parts due to the complexity involved.

Both have their places in the injection molding process, and both will be valuable tools to help you boost your injection molding production line.

Reference: