About

- Home

- About

Our Arttangent Electronic

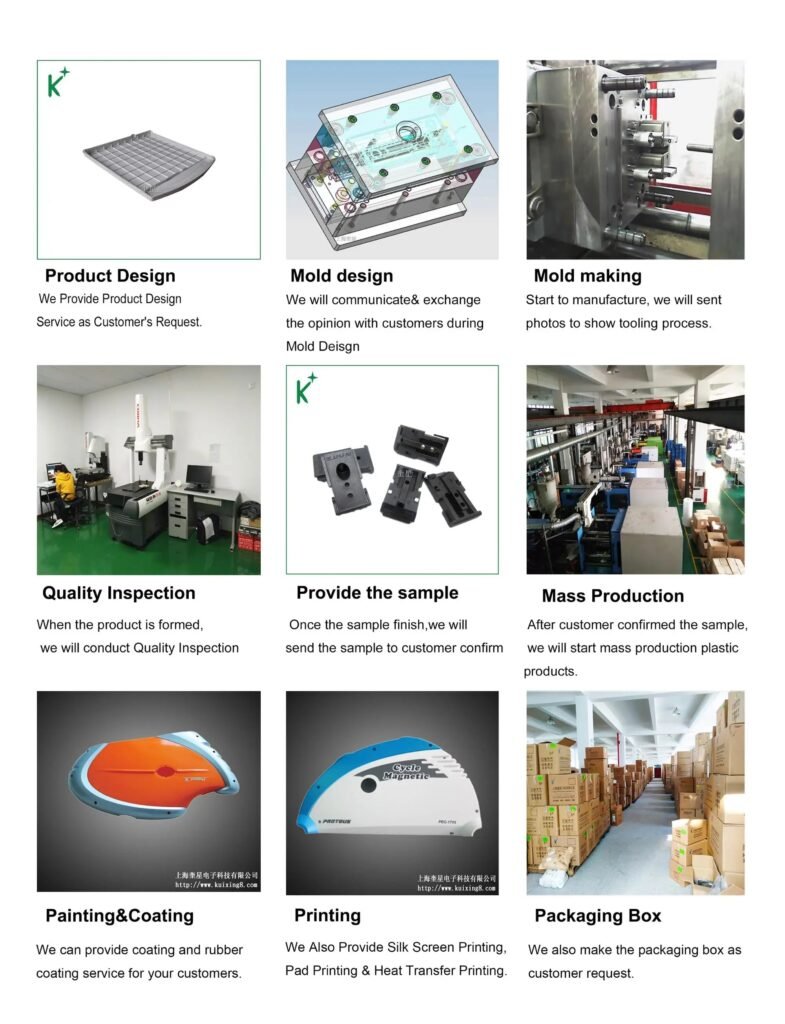

Shanghai Arttangent Electronic Technology Co., Ltd., established in 2001, is a company with a workforce of 100 employees. We hold certifications in ISO 9001:2008 and IATF 16949, demonstrating our commitment to quality and excellence. Our core competencies lie in the design and manufacturing of injection molds, plastic components, as well as services encompassing painting, printing, welding, hot stamping, laser etching, and assembly.

With a dedicated and skilled team, we are committed to delivering top-notch products and services. Our guiding principles are rooted in professionalism, integrity, and innovation. We are steadfast in our pursuit of process control, maintaining stable quality, and ensuring customer satisfaction.

Our overarching goal is continuous improvement, both in meeting our customers’ needs and contributing to society as a whole. We are unwavering in our commitment to upholding the highest standards of excellence.

Greeting From Founder

Arthur Li

Injection molding is one of the main methods of industrial supplies and daily necessities, so it is like a chef, is a never-unemployed industry. The future production of mold processing will be more humane energy saving and environmental protection direction, but these will only enhance the vitality of the mold injection molding processing industry, many industries once the technological change will have fatal injury, resulting in the decline of traditional industries to the elimination, but the mold industry will not, the future of the injection molding machine, blow molding machine, mold molding machine will be towards a smarter, low-noise, high-efficiency, safer, zero-pollution direction, but must be the development rather than elimination, this is our focus on this industry. Zero pollution in the direction of development, but it must be the development rather than elimination, which is also our focus on this industry for 10 years of power.

We Encourage The Change

- Injection Mold Workshop

“Mold, is a specific structural form through a certain way to make the material molding of an industrial product, but also can be batch production of industrial products with a certain shape and size requirements of the parts of a production tool. Large aircraft, automobiles, as small as tea cups, nails, almost all industrial products must rely on mold molding. With mold production parts with high precision, high consistency, high productivity is any other processing methods can not be compared. Mold to a large extent determines the quality of the product, efficiency and new product development capabilities. So the mold and the “mother of industry” honorary title.

- Class 100,000 medical injection molding workshop

“Injection molding machine is the most important production equipment in the process of injection molding, the injection molding machine can inject all kinds of different shapes of plastic parts, achieve perfect products!

- Paint spraying workshop

” Paint spraying workshop is the place for coloring and dressing your products. Here, we will beautify your products! And we do it without a trace.

- Print workshop

In printing design, it is customary to refer to other forms of printing expression other than those based on the principle of pressure as special processes, the main common ones being foil stamping, varnishing, embossing, embossing, die-cutting and so on. Different applications of the process will create different effects, these processes play an important role in enhancing the creativity and artistic value of the design work, so that the texture of the work produces a sharp contrast, more expressive, unique personality.

- Assembly Workshop

Assembly workshop is the integration of product parts, realize the product or part of the product process place, generally more in the assembly line. However, it does not have to be “assembly line”, the invention of the assembly line is to reduce the amount of labor of workers, but the wisdom of the Chinese people is only afraid to invent the assembly line of Ford to the death of anger, because now in China many assembly lines have become a burden on workers, the Chinese people are smart ah!

- Testing equipment

Arttangent insists on human quality control and controlled process. But this does not mean that Arttangent just to the human eye to determine the quality of the product, because there are many product defects is not visible to the human eye, or the human eye has a subjective error, in this regard, the machine to be better than the human eye, because the machine is more than the human eye in pursuit of objective facts.

Maintain The Quality Of Products

Quality Excellence: Rigorous Standards, Skilled Team, Continuous Improvement"

- Processing equipment: 3 sets of CNC milling, 3 sets of EDM, 4 sets of wire cutting, 2 sets of drilling machine (large) (small) 1 set, 2 sets of grinding machine, 2 sets of flying cutter, 2 sets of CNC machining center, 12 sets of injection molding machine.

- Processing capacity: injection mold design, injection mold manufacturing, product injection processing, paint processing, printing processing, assembly and packaging

- Mold material: NKA80 P20, 718, 718H, 2738, 2316, S136 and so on many kinds of material for your choice, mold frame: 45 # pre-hardened >30 HRC

- Cooling system: optimized design of circulating water flow, improve productivity and reduce your cost.

- Intermediate treatment: mold tempering, mold heat treatment, etc., to improve the hardness.

- Post-treatment: Nitriding (Nitriding treatment temperature is low, deformation is very small, no longer need to be quenched will have a very high surface hardness (greater than HV850) and wear resistance).

- Mold life: P20 normal use of not less than 500,000 die times

- Transportation: The air purifier molds must be installed before shipment of clamping piece, packaging, strong, rust-proof, logistics transportation.

- After-sales service: Mould warranty for life, large injection volume, free to open a copy of the mold.

They Trust US

Our Experienced Team

We have professionals with experience on our team. Each project benefits from their expertise and enthusiasm.

Arthur Li

CEO

Arttangent CEO at Arttangent (Shanghai) Technology Co., Ltd., excels in manufacturing excellence and strategic growth.

Amy Wang

SALES Manager

Sales Director at Arttangent, brings 20 years of marketing expertise, driving successful international sales strategies.

Mike Xu

Engineer

Factory Manager at Arttangent boasts over 20 years in mold factory management, excelling in product design, quality control, and innovation.