Blog

Author: chkuixing.com

Arthur Li

Focusing on the field of plastic injection moulds for 20 years, with rich practical experience and professional knowledge, to provide quality mould solutions for a number of enterprises

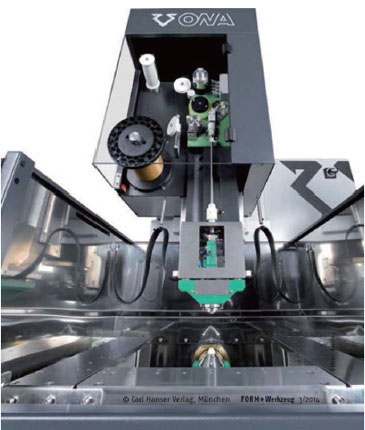

3D printing, also known as additive manufacturing, is the process of constructing an object that is three-dimensional from a CAD or digital 3D model. It can be accomplished by a variety of processes in which material is deposited, connected, or solidified under computer control, with the material added layer by layer (for example, plastics, liquids, or powder grains being fused).

3D printers are the future of the manufacturing industry, being one of the most disruptive pieces of technology in the last decade. 3D printing boosts production immensely, and it is also a highly scalable solution, which makes it an integral part of the modern supply chain. Naturally, it is also a new frontier in injection molding, and integrating 3D printing in your injection molding process is a great way to not only cut down on costs but also speed up production.

Featuring not just high production quality but also amazing scalability, injection molding is one of the most popular methods of production for manufacturing businesses. It is used extensively in industries such as car manufacturing and consumer goods, as a result.

Injection molding is not a new method of production, but it has certainly aged well, as adoption is increasing on a worldwide scale. In this USA injection molding report, we will go through all the past growth of the USA injection molding market, as well as some industry trends and predictions that will become useful to you as a business owner down the line.

The injection molding process is a manufacturing technology that enables large-scale production of items. It operates by pumping molten materials into a mold (or ‘mould’ in the United Kingdom). It is commonly used as a large-scale manufacturing method to create thousands of similar things. Metals, glasses, elastomers, and confections are among the materials that can be injected molded; however, thermoplastic and thermosetting polymers are the most frequently used materials.

You might be wondering “ What are the best injection molding companies near me in Shanghai?” Well, in today’s article we’re going to answer this question of yours.

Because in this article we’ve compiled a list of the best injection molding companies in Shanghai that can help you launch your project right away.

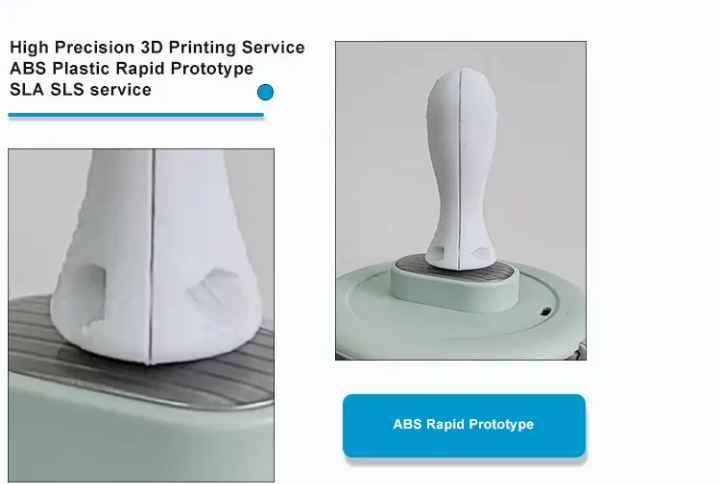

If you’re looking to launch your product soon, it might be a good idea to have a few prototypes at hand. After all, you wouldn’t want the design to come out different than your imagination right? But getting prototypes might not be as cost-friendly as you would want it to be, that’s why at Kuixing Electronics we often advise our customers to use rapid prototyping.