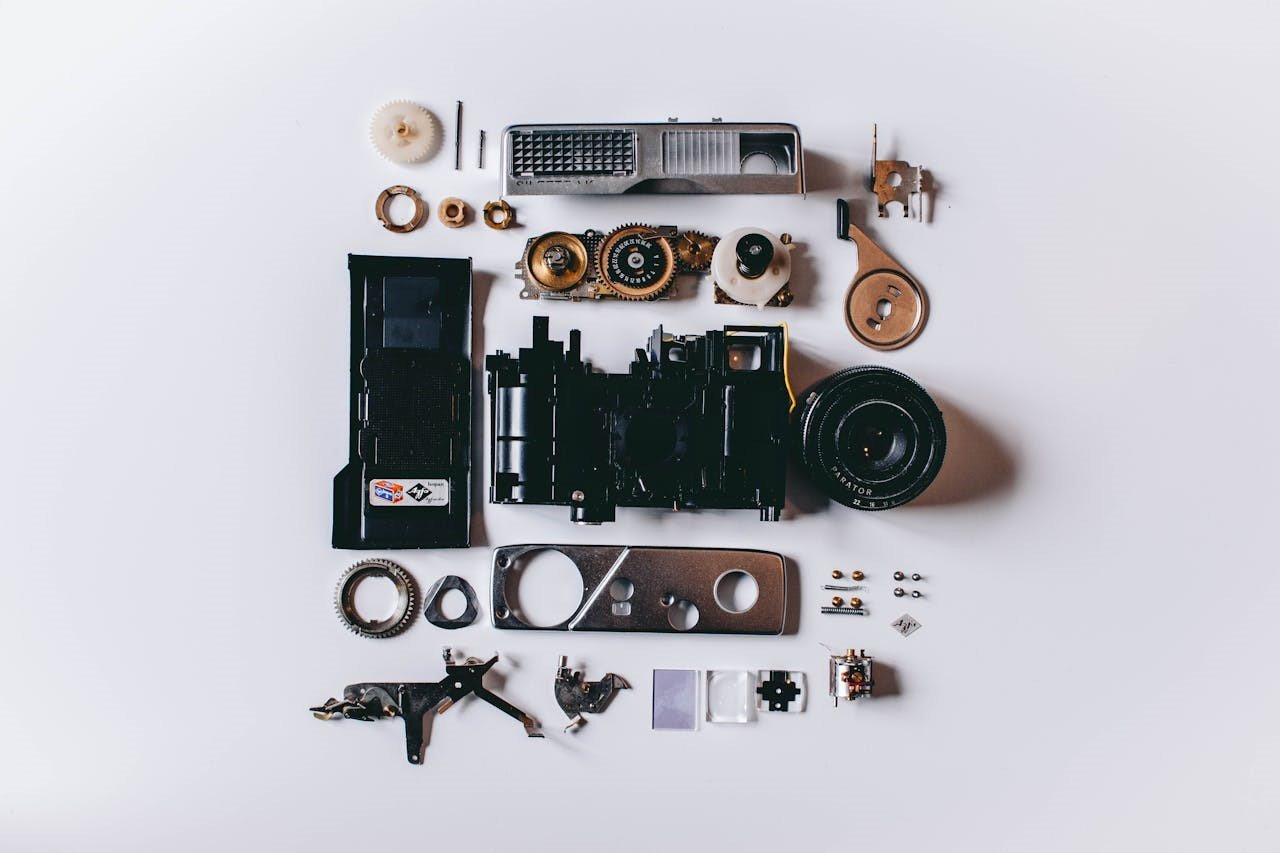

Cars are an integral part of most society. Cars not only help us move around but they also help us to transport goods efficiently from one place to another. It certainly is hard to imagine a world without cars. However, car parts manufacturing is a major pollutant in our current world, causing major environmental impacts.