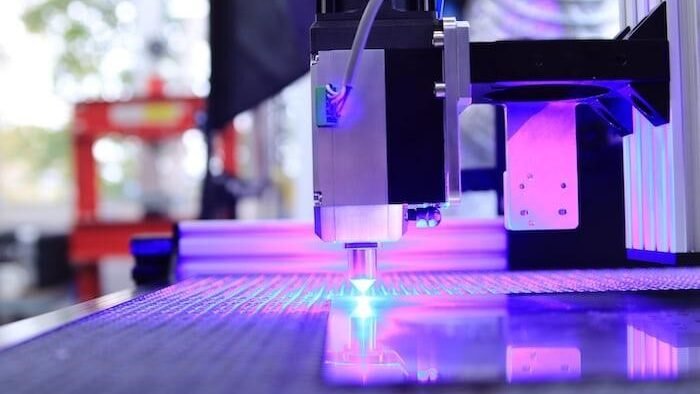

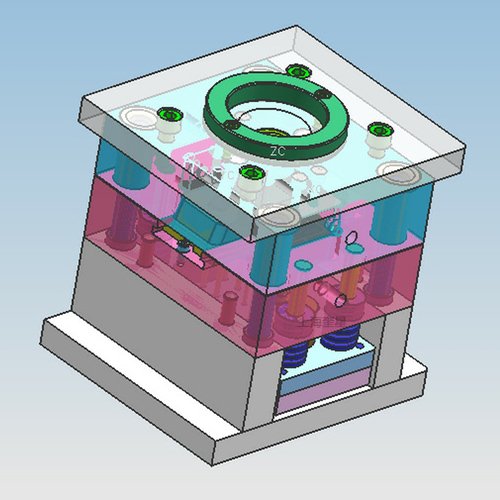

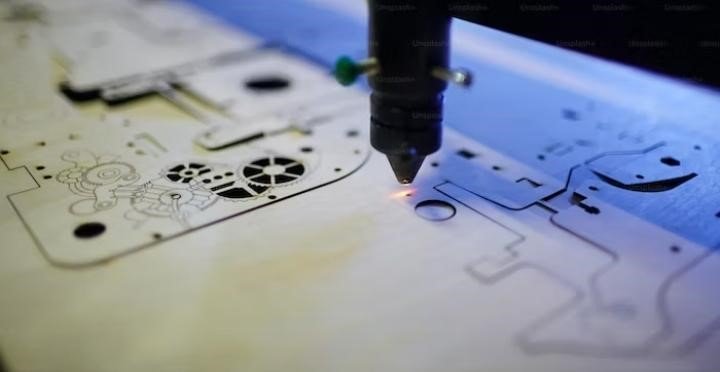

CNC stands for Computerized Numerical Control. A CNC machine is a device that is used for pre-programmed computer software manufacturing that dictates the movement of factory tools and machinery. A CNC machine is an instrument that is suitable for a wide range of materials like metals, wood, plastic, foam, and glass. It uses computerized machines and control systems to remove layers of materials for an object known as a workpiece or blank.