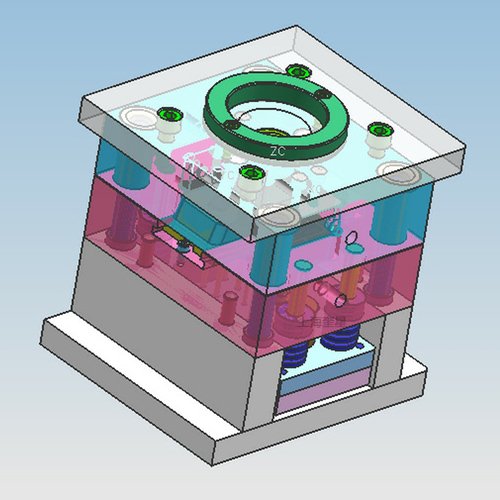

3D printers are the future of the manufacturing industry, being one of the most disruptive pieces of technology in the last decade. 3D printing boosts production immensely, and it is also a highly scalable solution, which makes it an integral part of the modern supply chain. Naturally, it is also a new frontier in injection molding, and integrating 3D printing in your injection molding process is a great way to not only cut down on costs but also speed up production.