Engineering design fees generally include: 1) product appearance design fees, 2) product structure design fees, 3) product mold design fees.

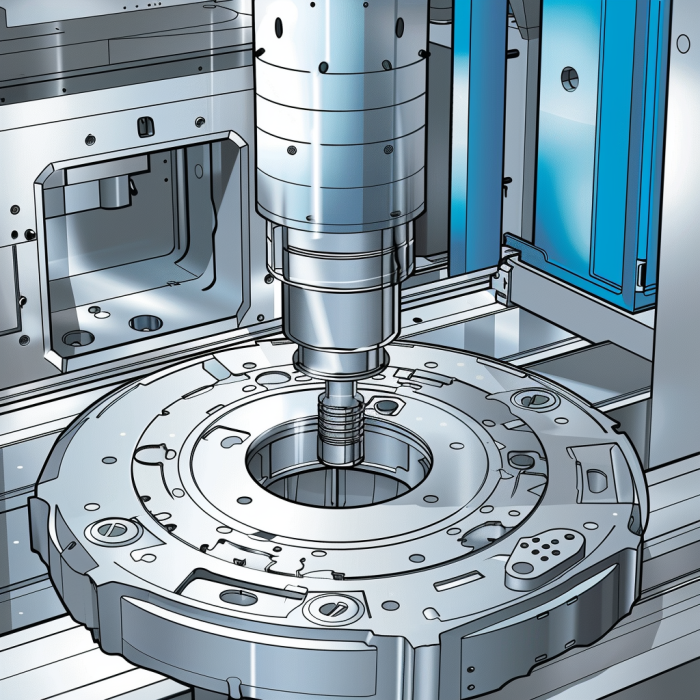

The quality of injection molds is related to many factors, under the same circumstances, the quality of the produced molds is directly related to the design. In addition to designers needing a rich theoretical foundation and practical experience, the design concept of the mold is also crucial, mainly including the following aspects:

(1) Analyze the pattern structure of plastic parts, such as: draft angle, material level thickness, etc.

(2) Plastic varieties of plastic parts. Determine shrinkage, understand flow, gate size and location, and more.

(3) Understand the specifications of the injection molding machine.

(4) Number of cavities and ranking method. It is determined based on the output of plastic parts and the location of the gate.

(5) Runner method and gate design

(6) Determination of parting surface

(7) Design of molded parts

(8) Side core-pulling design

(9) Release method

(10) Exhaust design

(11) Design of cooling and heating systems

(12) Determination of processing technology

(13) Drawing of 2D and 3D assembly drawings of molds

(14) Check by relevant engineering and technical personnel

(15) Mold steel. Select steel materials based on the output of plastic parts, types of plastics, etc.