Contents

Key Steps to Enhance the Manufacturing Precision of Injection Molds for High-Quality Plastic Parts

Factors With Strong Impacts on Your Injection Molding Manufacturing Precision

Material

Technical Expertise

Cooling Process

How to Improve the Precision of Your Injection Molding Process

Select The Right Materials

Constantly Monitor the Process

Pay Close Attention to the Injection Phase and the Cooling Phase

Factors With Strong Impacts on Your Injection Molding Manufacturing Precision

Injection mold is the manufacturing method of the future, as it offers unrivalled precision as well as scalability. In fact, many cutting-edge technologies are being developed by industry leaders to improve the process even further, particularly in the automation aspect of the process. If you wish to fulfill massive orders with complex geometry and design, injection molding should be your method of choice.

However. That does not mean high-precision and manufacturing quality for injection molding is locked behind expensive technologies and tools. There are some key steps you could take to enhance the manufacturing precision of your injection molding process to create high-quality plastic parts with ease.

Factors With Strong Impacts on Your Injection Molding Manufacturing Precision

Injection molding is a great manufacturing process with plenty of room for automation. Here are some factors that play a pivotal role in determining the precision of your injection molding process.

Materials

The materials do matter a great deal, as not all materials are made equal. Some are quite easy to work with, such as most thermoplastic materials. Others are much more difficult to work with and thus would require a lot more expertise in handling them. Thermoplastic materials are also much more malleable compared to molten metals and resins, so they are easier to control in terms of molding.

The material of the mold itself is also another important factor that you have to take into account. Steel molds are much more durable than aluminum molds, so they offer great value for money in the long run. That said, they are also not very flexible, so you won’t be able to repurpose the mold to accommodate another design down the line. Conversely, aluminum molds are more flexible, but they lack ruggedness and durability.

Technical Expertise

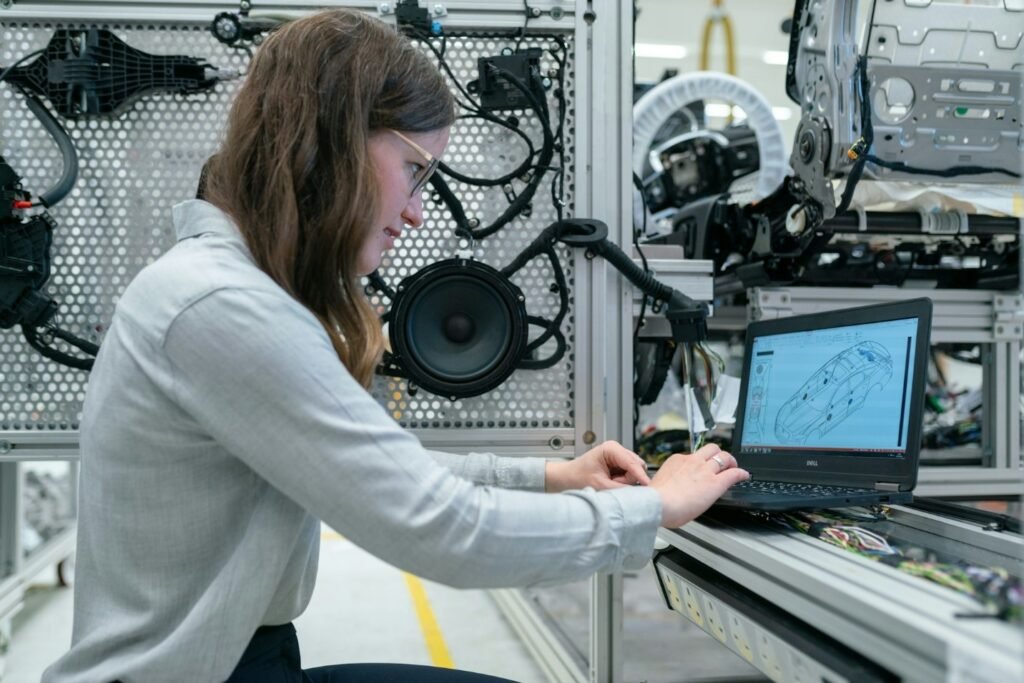

Even though the injection molding process is largely automated now, some steps within the process will have to be done or monitored by human experts. If these experts lack the technical expertise needed to operate the injection molding manufacturing line, you will not be able to ensure a high level of manufacturing precision throughout the whole process.

Cooling Process

The cooling process is where there is a lot of room for error. After the molten materials have been poured into the mold, engineers will run coolants around the mold to cool down the temperature and let the molten materials solidify. If the cooling process is not done properly, chances are that there will be warpage as well as some degree of shrinkage in the finished products, which can cost you your deal with customers.

How to Improve the Precision of Your Injection Molding Process

Now that we have identified the key factors that affect not just the precision of the process but also the overall quality, let’s take a look at how you can improve the manufacturing precision of your injection molding process without having to spend a fortune on cutting-edge technology.

Select The Right Materials

As established above, materials are crucial to the entire injection molding process because they can determine the length of the cooling process as well as the properties of the finished products. When you receive your orders and requirements from customers, take a moment to consider the best materials that go well with this product. Take into account the thickness, melting point, chemical properties, etc. of the potential materials. You will be able to not only increase the quality of your finished products but also optimize the manufacturing process to be as precise as possible.

Do keep in mind that some materials allow mixing and blending, which alter their properties in many ways. You can leverage these techniques to create the perfect material mix for your project.

Constantly Monitor the Process

The injection molding process is full of different parameters to monitor, and if even a single one of them is slightly off the scale, there will be chances of warpage and defects in the end products. To prevent this, you will have to employ a team of highly qualified engineers with a clear understanding of the process as well as what each parameter stands for. These engineers will constantly monitor the injection molding process to make sure that everything is going smoothly, and if a single parameter is going off the chart, they will be able to apply fixes right away.

Pay Close Attention to the Injection Phase and the Cooling Phase

These are the two phases where a lot of things can go wrong. The injection phase is when you inject the molten material into the mold cavity to let it fill the mold. In this phase, if the injection pressure is too high, the material might overflow, causing excess material to drip out of the mold. Thus, you will have to keep an eye out for the injection pressure at this phase.

In the cooling phase, the material will begin to solidify and form the finished products. If the coolants cannot reach all parts of the mold, inconsistent cooling will occur, causing warpage and shrinkage at various points on the products. To fix this issue, you can design a cooling system that specifically spreads coolants evenly across all parts of the mold cavity, making sure that every area receives coolants evenly.

The key steps to enhance the manufacturing precision of injection molding are selecting the right materials, constantly monitoring the entire process, and paying close attention to the injection and cooling phases, where a lot of things could go wrong.

The tools as well as the mold used for the injection molding process are also key components to your success as an injection molding manufacturing plant. Good mold design will ensure that all areas of the mold receive cooling evenly and consistently, preventing common issues such as warpage. If you wish to minimize the risk of defects and errors to a minimum, get the best injection molds as well as tools for your business first before starting your own production line!

Reference: