Outline:

- What is a 3D printing service

- What are the benefits of 3D printing service

- How does the 3D printing service work

- Online 3D printing service at Kuixing Electronics

- Conclusion

What is a 3D printing service

3D printing, also known as additive manufacturing, is the process of constructing an object that is three-dimensional from a CAD or digital 3D model. It can be accomplished by a variety of processes in which material is deposited, connected, or solidified under computer control, with the material added layer by layer (for example, plastics, liquids, or powder grains being fused).

This process is used to manufacture prototypes mainly so that you can analyze the final product before large-scale manufacturing. It is used all over the world to make custom parts.

What are the benefits of 3D printing service

- Flexible Design

3D printing enables the creation and fabrication of more complicated designs than traditional manufacturing procedures. More traditional techniques have design constraints that 3D printing eliminates. - Rapid prototyping

3D printing can produce parts in hours, accelerating the prototyping process. This allows each step to be Tum quicker. When compared to machining prototypes, 3D printing is less expensive and faster to create parts because the parts may be finalized in hours, allowing each design alteration to be performed at a much faster rate. - Produce on Request

Another benefit of print-on-demand is that, in contrast to traditional production methods, it doesn’t require a lot of room for inventory storage. Because there is no need to print in volume unless necessary, this saves money and space.

Since the 3D design files are printed using a 3D model as a CAD or STL file, they are all kept in a virtual library where they may be found and printed as needed. By modifying individual files, changes to designs can be done at extremely low prices without wasting outdated inventory or purchasing new tools.

- Strong and Lightweight Parts

Plastic is the most common 3D printing medium, however, other metals can be used as well. However, plastics have an advantage over metals since they are lighter. This is especially essential in industries like automotive and aircraft, where low weighting is an issue and can result in increased fuel efficiency.

Parts can also be made from specialized materials to have certain features like heat resistance, increased strength, or water repellency.

- Cost-effective 3D printing with laser-direct deposition.

As a single-step production method, 3D printing saves time and money compared to employing several pieces of equipment. 3D printers may also be set up and left to get on with the job, which means that operators do not have to be there the entire time.

How does the 3D printing service work

There are more than a dozen different 3D printing technologies in use today. 3D printing first appeared in the early 1980s to replace hand-made models, custom parts, and prototypes carved from wood or pasted together with bits of card or plastic.

3D printing is a logical outgrowth of rapid prototyping (the automated development of models and prototypes). The result is a savings of both time and money. 3D printing has become widely used in engineering, manufacturing, commercial, and even personal applications.

3D printing is accomplished by the process of additive manufacturing, a method in which material is united under computer control to form a three-dimensional item. The materials, which range from liquid resin to powdered grains, are fused layer by layer. A digital 3D model or CAD file can easily be printed into a variety of shapes, including very complicated ones.

3D printers create a three-dimensional object one layer at a time, beginning at the bottom and progressing upward.

Printer Types

There are approximately a dozen 3D printing machine types utilized to create 3D custom parts. Here are some of the more frequent and popular 3D printing technologies, which use either plastic resin or a material powder to generate three-dimensional items from computer files.

FlashForge Finder: 3D Printer

Fused deposition modeling (FDM) is the most popular and widely available type of desktop 3D printing on the market. Fused deposition modeling, which was developed and first applied in the 1980s, allows you to print both functioning prototypes and ready-to-use goods such as LEGO bricks, plastic gears, and much more. All components printed with FDM can be made of high-performance, engineering-grade thermoplastic, making this technique helpful for mechanical engineers and manufacturers.

Printed parts have exceptional mechanical strength and thermal resistance. FDM printers use thermoplastic filament to build 3D objects layer by layer, beginning at the bottom and working their way up. This type of 3D printing is beneficial in a wide range of applications, including new product development, prototyping, and end-product manufacture.

Stereolithography (SLA)

It is the oldest method of 3D printing. It works by exposing a layer of photosensitive liquid resin to a UV laser beam; the resin hardens in the desired pattern, and the object is built up layer by layer until it is finished. SLA 3D printers produce smooth surfaces, although the quality varies depending on the printer type. Printing using SLA takes longer since produced objects must be washed with a solvent before being placed in a UV oven to complete the process.

Stereolithography (SLA)

It is the oldest method of 3D printing. It works by exposing a layer of photosensitive liquid resin to a UV laser beam; the resin hardens in the desired pattern, and the object is built up layer by layer until it is finished. SLA 3D printers produce smooth surfaces, although the quality varies depending on the printer type. Printing using SLA takes longer since produced objects must be washed with a solvent before being placed in a UV oven to complete the process.

Digital Light Processing (DLP)

It is the fastest 3D printing process. A layer of hardened material can be printed in a matter of seconds and swiftly transferred to allow for printing the following year. DLP 3D printers, like SLA, use liquid plastic resin but melt it with arc lamps rather than a UV laser beam. This light source lets the resin harden quickly, resulting in amazing printing rates. DLP is a dependable technique that consistently creates high-resolution models, allowing you to employ cheaper materials for complicated and detailed things.

Selective Laser Sintering (SLS) technique

Like other printing technologies, it constructs items layer by layer, but with one important difference: it uses powdered material instead of liquid resin. SLS prints sturdy 3D things from powdered material using a laser, eliminating the need for extra support structures. SLS is popular for printing bespoke goods because it allows for the use of a wide range of materials, including nylon, glass, ceramic, aluminum, silver, steel, and more.

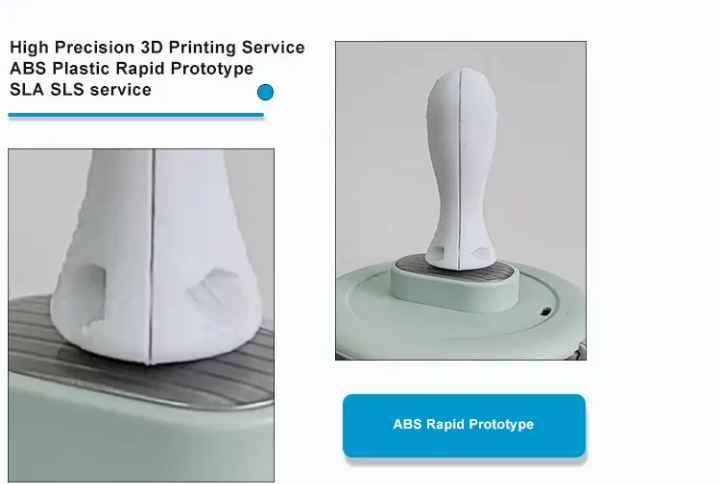

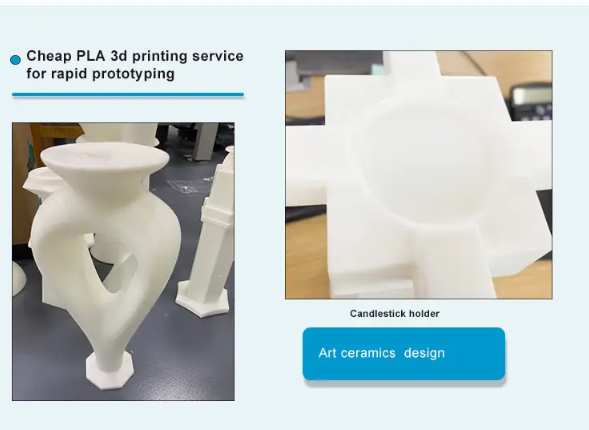

3D printing service at Kuixing Electronics

You can get all kinds of 3D printing services for your products at Kuixing Electronics, Shanghai China, at the best rates. The best part is you can do all this without having to visit in person through ONLINE 3D printing services. All you need to do is contact us to discuss the 3D printing service that is best suited for your products. Our team of experts is ready to guide you throughout the whole process. So, book your call by clicking here.

You can also click on this video to get a real-time view of how our 3D printers work.

Conclusion

To sum it up, the emergence of online 3D printing services, exemplified by Kuixing Electronics, has revolutionized manufacturing, especially in the realm of custom parts. The array of advantages, from flexible design to rapid prototyping, on-demand production, and the creation of robust yet lightweight components, underscores the widespread applicability of 3D printing across diverse industries. Delving into various 3D printing techniques like Fused Deposition Modeling (FDM), Stereolithography (SLA), Digital Light Processing (DLP), and Selective Laser Sintering (SLS) highlights the versatility of applications and materials for crafting intricate, tailor-made products. With continuous technological advancements, these services not only offer cost-effective solutions but also streamline processes, providing indispensable support for businesses seeking efficient and innovative manufacturing solutions for custom parts.

External links:

1. https://www.economist.com/technology-quarterly/2013/09/05/3d-printing-scales-up

2. https://web.archive.org/web/20201104031948/http://wohlersassociates.com/NovDec05TCT3dp.htm

3. https://youtu.be/Dv9Y_hO4ooE