Description

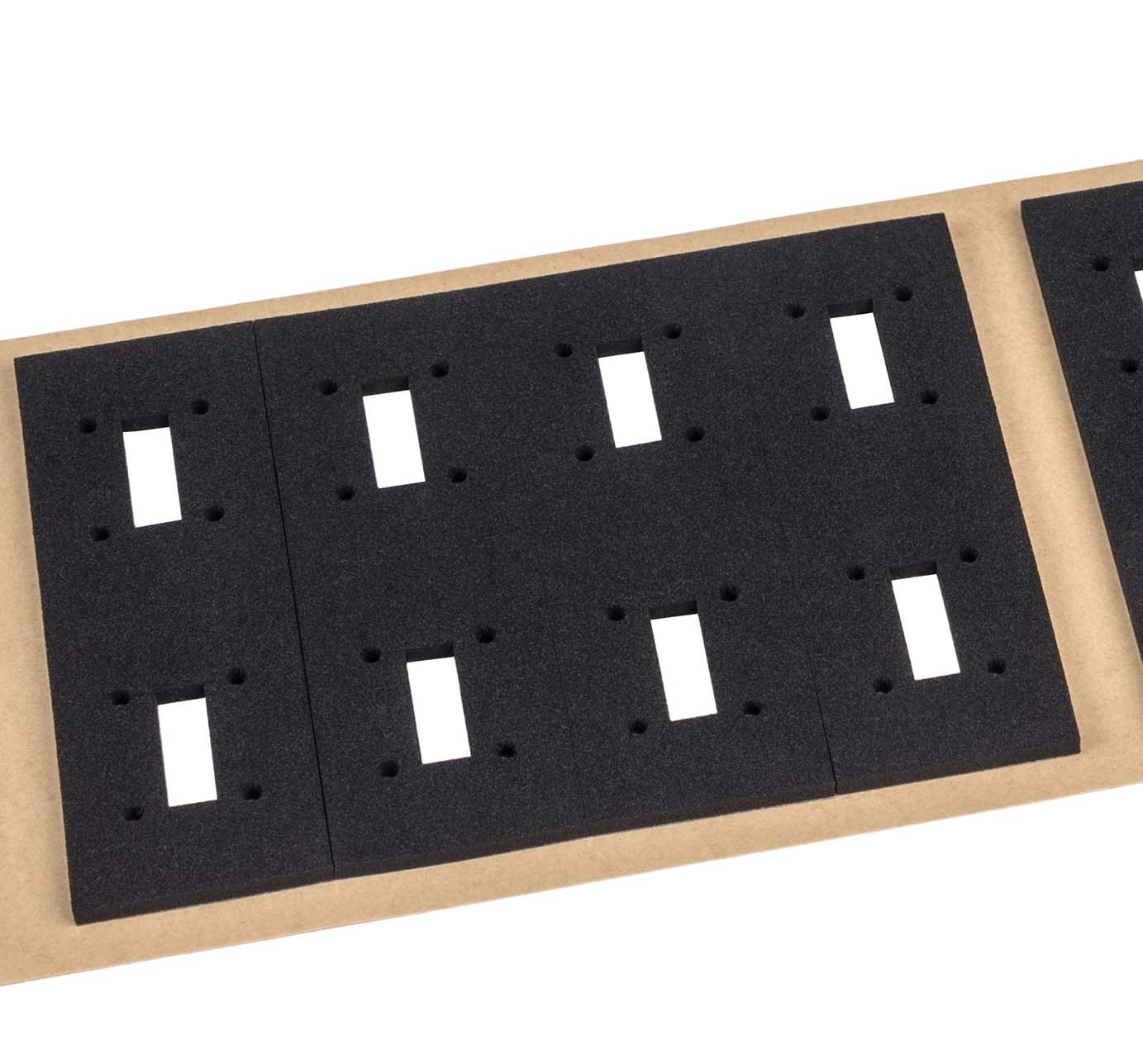

Custom Die Cutting and Gasket Fabrication

1.Precision Die-Cutting Services

Die cutting is an staple and specialty, the first and often best option for cutting non-metallic sheet products into mass-produced custom shapes. After laminating your chosen material with pressure-sensitive adhesive and removeable liner, die-cutting the converted material is the final step to creating a peel-and-stick gasket or seal for easy assembly.

2.Rotary Die-Cutting Services

Highly repeatable, precise and versatile: rotary die-cutting services make it possible to produce high volumes of identical parts from flexible material, while also meeting your most stringent tolerance standards.

3.Waterjet Cutting ServicesWith waterjet cutting capabilities, we make it possible to get precise cuts from flexible material that’s too thick or rigid for die cutting, and optimize material yields of your custom converted materials.

4.Custom Laser Cutting Services

laser cutting services are a great option for small and low-volume production runs. Laser cutting is also the go-to for rapid prototyping and part sampling. How does it work? Laser cutting uses software-guided fabrication, cutting design from the flat material with a laser beam. That means production can commence as soon as the material is available, making it a faster option than die cutting.

5.Automatic Slitting Services

When your application calls for strips of non-metal material — or you simply need a certain-sized roll of tape that’s unavailable from the manufacturer — lathe slitter handles a wide range of materials in varying diameters, thicknesses and widths to get the job done. Our single knife lathe slitter cuts coils of foam rubber and adhesive tape from a master roll to the desired width — down to the nearest .3MM.

6.Reciprocating Knife Cutting Services

Reciprocating knife cutting uses an oscillating knife that’s guided by computer software. With no expensive metal die to fabricate, knife cutting production can commence with minimal lead time — all that’s needed are the materials and a completed CAD. Reciprocating knife cutting is the go-to for larger gasket shapes, as well as small to medium production runs, rapid prototyping and the product samples.

At Standard Rubber Products, we have served original equipment manufacturers with high-quality materials, components and subassemblies. We provide creative die-cut products and unparalleled service, with special expertise in gaskets.

We master all cutting technologies: flatbed die-cutting, rotary die-cutting, laser die-cutting in scrolling mode, digital cutting (without tools), die-cutting of foams and rubbers into blocks. we are able to manufacture complex parts (up to 18 materials and 8 tools in the same process).

Moreover, our ability to offer a wide choice of adhesive materials (foam, rubber, plastic or metallic film, textile, non-woven, felt, acoustic fabric, etc.) and a precision in line with their needs allows us to meet the specific and complex expectations of our customers.

Air and watertightness, soundproofing and noise reduction, cladding and decoration are functions that we fulfil on a daily basis. The developments in our laboratory and the expertise of our R&D departments allow us to take into account all the specifications and needs of our customers in order to provide high quality automotive adhesive tapes.

Some application examples:

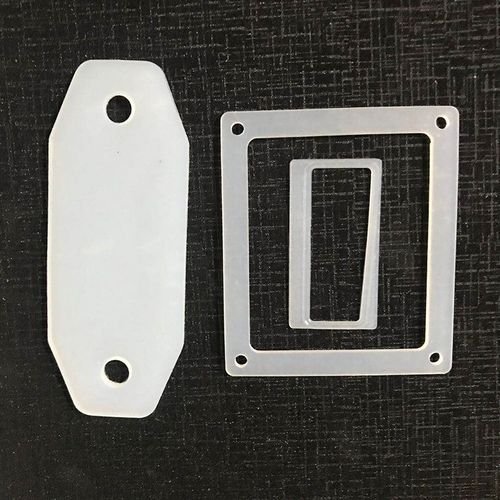

Adhesive water seal

- Adhesive gasket made of EPDM cellular rubber

- Waterproofing of third break lights, rear light, bumpers or many other automotive applications.

Air sealing gasket

- Door mechanism gasket in EPDM compact rubber + Gergonne adhesive tape

Sound dampening solution

- Non-woven adhesive tape for application on car consoles

- Solution for damping impact noise

Adhesive tape solution – hole sealing

- PE foam adhesive tape for car bodywork obturator

Reviews

There are no reviews yet.