1. Empirical calculation method

Mold price = material fee + design fee + processing fee and profit + value-added tax + trial mold fee + packaging and transportation fee

The proportions of each item are usually: Material cost: materials and standard parts account for 15%-30% of the total cost of the mold;

Processing fee and profit: 30%-50%;

Design fee: 10%-15% of the total mold cost;

Trial mold: Large and medium-sized molds can be controlled within 3%, and small precision molds can be controlled within 5%;

Packaging and transportation fees: can be calculated based on actual calculation or 3%; Value-added tax: 17%

2. Material coefficient method

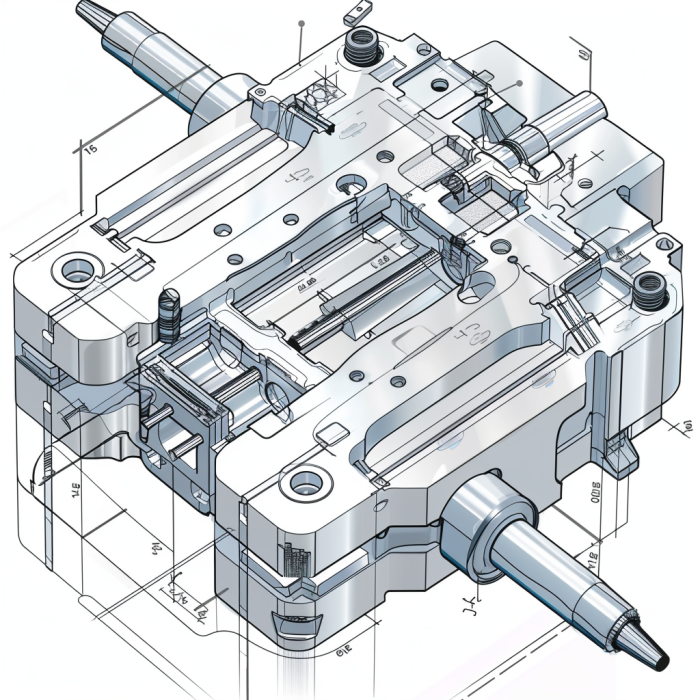

The mold material cost can be calculated based on the mold size and material price.

Mold price = (6~10)*material fee Forging mold, plastic mold = 6*material fee Die-casting mold = 10*material fee

Mold quotation estimate

1. First of all, we must look at the customer’s requirements, because the requirements determine the choice of materials and heat treatment process.

2. Select the materials, draw up a rough mold plan, and calculate the weight of the mold (calculate the price of the mold core material and mold base material) and the cost of heat treatment. (Both are rough weights)

3. Processing cost. Depending on the complexity of the mold core, the processing cost is generally 1.5~3:1 with the price of the mold core material. The processing cost of the mold base is generally 1:1.

4. The risk fee is 10% of the total price above.

5. Tax

6. The design fee is 10% of the total price of the mold.

Mold quotation strategy and settlement method

The quotation and settlement of the mold are the continuation and result of the mold valuation. From the valuation of the mold to the quotation of the mold, it is only the first step, and the ultimate goal of the mold is to form the final settlement price of the mold through settlement after the mold is manufactured and delivered for use. In this process, people always hope that mold valuation = mold price = mold settlement price. In actual operation, these four prices are not exactly equal, and fluctuating error values may occur. This is the issue discussed below.

After the mold is appraised, it needs to be properly processed and compiled into a quotation for the mold, which will serve as a basis for signing the mold processing contract. After repeated discussions, a mold price agreed upon by both parties was finally reached and a contract was signed. Only then can the mold processing be officially started.

4. lifetime of the mold

Arthur’s feedback: Mold life, generally ranges from 100,000 mold times to 1 million mold times