Outline:

- What is a CNC machine?

- The benefits and uses of a CNC machine

- The parts of a CNC machine

- Different types of CNC machine

- Conclusion

CNC stands for Computerized Numerical Control. A CNC machine is a device that is used for pre-programmed computer software manufacturing that dictates the movement of factory tools and machinery. A CNC machine is an instrument that is suitable for a wide range of materials like metals, wood, plastic, foam, and glass. It uses computerized machines and control systems to remove layers of materials for an object known as a workpiece or blank.

CNC is a type of programming in which the numerical systems usually believe that the processes are error-free despite the probability of fault, which becomes greater when the CNC machine is used for cutting in more than one direction at the same time.

The Benefits and Uses of a CNC machine:

A CNC machine can be a very useful tool and it is used for several reasons and its large benefits some of the best benefits of a CNC machine are:

- A CNC machine helps to make long-lasting items like artificial joints, aerospace mobiles, and automobiles.

- A CNC machine improves accuracy and speed of production which is quite advantageous to many industries.

- Due to the increased efficiency of a CNC machine, a lot of cost is saved up by companies.

- CNC machines allow for quick production changes.

- These machines can work 24 hours a day, 7 days a week, and 365 days a year.

Because of the advantages of these machines, they are used in every part of the world and are very popular nowadays.

The benefits of a CNC machine following the price depends a lot on the location of the company.

By default, companies in the US charge more for the same services than companies in East Asia. The biggest CNC machine service provider is China in the global manufacturing market. With its big labor force and huge trackrecord in the manufacturing industry, China stands as the first choice when it comes to CNC machine services. You can view the CNC product of Kuixing Electronics here

Parts of a CNC machine:

13 fundamental parts are common in every CNC machine. The list of these is:

- Input device:

Input device stands for how programs used in CNC machines are loaded into other machines. Input devices can be a USB cable (used to transport data between two computers), a keyboard (to write the G-code commands), or wireless communication.

- MCU (Machine Control Units) :

It is a set of devices both hardware and software which can be used to read the G-code commands delivered by the input device. It also translates it into instructions, so these commands can be performed by tools to execute the desired actions.

- Machine Tools:

Tools that do a process on a workpiece, include mostly cutting tools. These machine tools can be in many forms depending upon the CNC machine.

Machine tools are often found in the tool libraries where racks are used to store all the tools.

- Driving System:

The driving system means the motors that move the tool around the many machine axes. The movement of the driving system depends upon the type of CNC machine being operated.

- Feedback System:

A system that gives the feedback of any work being done in a CNC machine is known as the feedback system. Regardless of the precision of the driving system, it is still important to have a closed-loop control system, so the machine can easily move the components to their specific positions.

- Display Unit:

A screen is present in the CNC machine which displays all the important information to the operator.

Some display units with high resolution can provide a lot of information, on the other hand, some display units only show barely the important things.

- Bed:

In a CNC machine, the bed is where the machine parts are mounted. Numerous jigs are used for holding the workpiece in place. The bed contains holes or t- t-slots from which jigs are attached.

- Headstock:

In CNC machines a unique section is present attached to a lathe which contains the main drive, bearing, and gears which are used to rotate the chuck at the required speeds for machining, this section is called the headstock.

- Tailstock:

A Tailstock is an instrument that is used to support long vertical and cylindrical workpieces on one side while the chuck supports the other side while rotating.

- Tailstock Quill:

The tailstock quill is present within the tailstock. When a long shaft is being worked on, the conical-shaped quill fixed with the chuck axis is used for support.

- Pedal:

Chuck and tailstock quill can be activated and deactivated with the help of a foot switch. Pedals help to load and unload the parts of a machine.

- Chuck:

Chuck is a lathe-specific part that performs the function of tightly holding the raw material while it is being machined on a lathe.

It is attached with a spindle which helps it to rotate at a fast speed.

- Control Panel:

The input device, keyboard, display Unit, and other buttons which help to operate, are collectively called the control panel.

Types of CNC machines:

CNC machines are available in a large variety. They range from small mills to high-powered units with multiple devices.

1.CNC Milling Machine:

The most common CNC machines are CNC mills which are used for drilling, milling, and cutting operations.

Most of these machines include 3 hand movements.

Common CNC milling machines include universal, plain, and hand they include features like drilling, face milling, and turning.

2.CNC Lathe Machines:

CNC lathe machines can work on articles of all shapes but they work best for the flat, conical, and cylindrical products.

They do their work by rotating the workpiece on a central axis and after cutting, it is shaped in the required shape.

3.CNC Plasma Cutters:

These machines use an electrical discharge arc to produce a highly accurate cut, which ionizes the air and melts any material that it strikes.

They are used in the manufacturing of automobiles and automotive repair, fabrication, and scraping.

4.CNC Drilling Machines:

It is understood from the name that it is used for drilling holes in all materials for screws, assembling parts, and also for aesthetic purposes.

They use rotating drill bits to make perfect-sized holes.

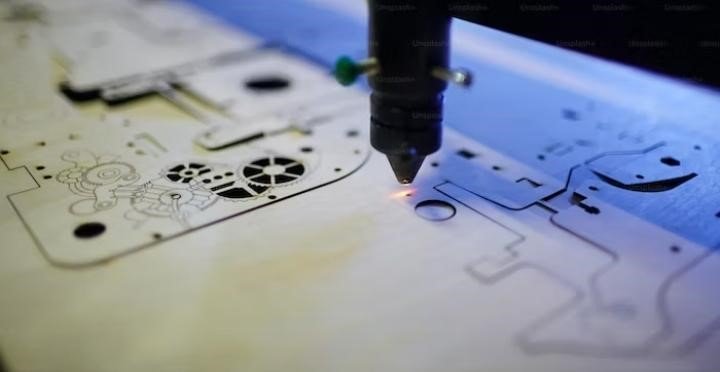

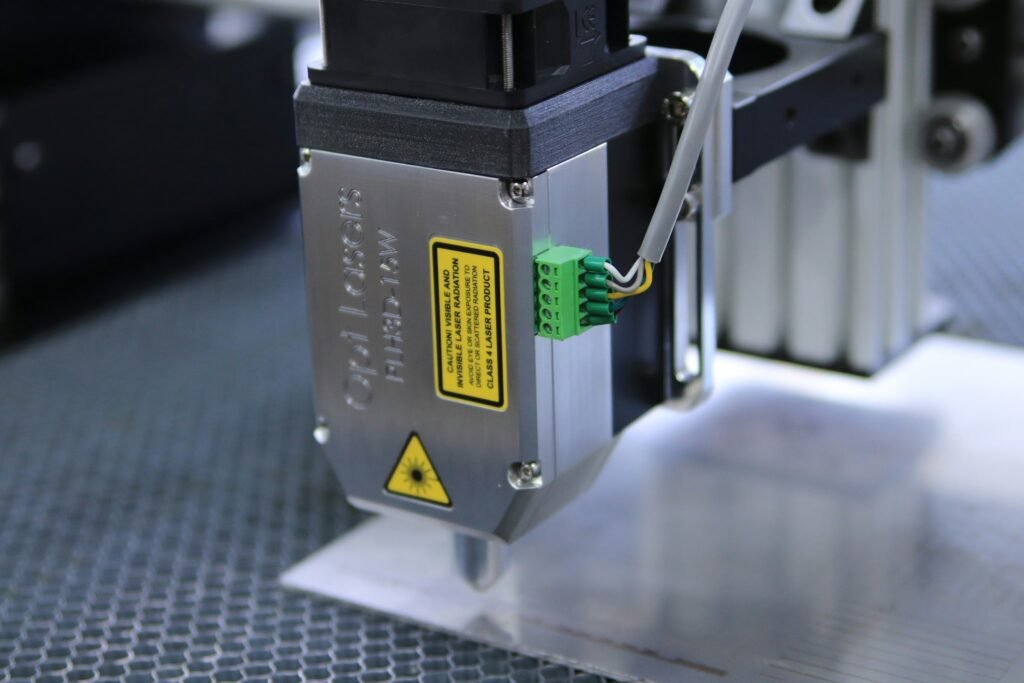

5.CNC Laser Cutting Machine:

Just like the CNC plasma cutting machines, these machines can cut through materials finely such as paper, plastic, metal, and hardwood.

They are used in aerospace parts, frames of automobiles, and engraving materials.

Most of these varieties are available in Kuixing Electronics, still, it might be a great idea to send us a message about your specific product or machine.

Conclusion:

In conclusion, CNC machines, which stand for Computerized Numerical Control, are versatile devices used in various industries for manufacturing processes. These machines utilize pre-programmed computer software to control the movement of tools and machinery in factories. CNC machines are capable of working with a wide range of materials, including metals, wood, plastic, foam, and glass.

Reference:

https://en.m.wikipedia.org/wiki/Numerical_control

https://www.safeguardglobal.com/resources/top-10-manufacturing-countries-in-the-world-2023/