Outline

- Is injection molding really expensive? Why?

- Factors that affect injection molding cost

- Why the price is worth it

- Tips to reduce the cost

- Conclusion

If your project involves plastic injection molding, then right now one factor must be bothering you; the cost. While injection molding plastic seems like the ideal solution for most projects, the price usually makes the stakeholders wonder if the process is worth it.

The answer is yes, it is worth it. Although plastic injection molding is an expensive process, the price is justified. Simply speaking, to launch a successful injection molding tool, we’ve to get some high-grade raw products to make the molds and we’ve to go through a lot of planning followed up by some expert labor and oversight. As a result, the price of the project is usually high.

Factors that Affect Injection Molding Cost

For us to justify the cost of injection plastic molding, we’ve to look at the breakdown of the factors that affect the process. The following factors are what make injection molding plastic so expensive:

1. Material of molds:

The process works by putting tons of pressure on the injection molds. So, the molds need to be strong and durable otherwise they’ll break down after just a few cycles. As a result, the molds are made from high-grade metals which increases the price of the project. The quality of the molds can’t be compromised especially if you plan to manufacture a large number of products.

2. Construction of molds:

As stated earlier, plastic injection molds are the most important part of the injection molding process. An expert team like Kuixing Electronics is needed to properly construct the moldsThey need to be highly durable and strong. To accommodate the hot plastic, every mold has a cavity, sometimes even more than one, that is used in a single cycle. This cavity has to be ground, polished, and machined to exact specifications.

The process starts on an engineering table with a detailed idea of the optimal cavity size and quantity for your specific project. The process mainly depends on its overall size and shape. The cavities of large, complex plastic components must be machined and polished with great precision. Components like slides, lifters, and cams; devices that facilitate the creation of undercuts, are incorporated; the molds become complex. Massive, pricey CNC machines operated by metalworking specialists are required for the majority of large-scale molds, the market price of this process ranges from 100$ to 100,000$ depending on the type or product.

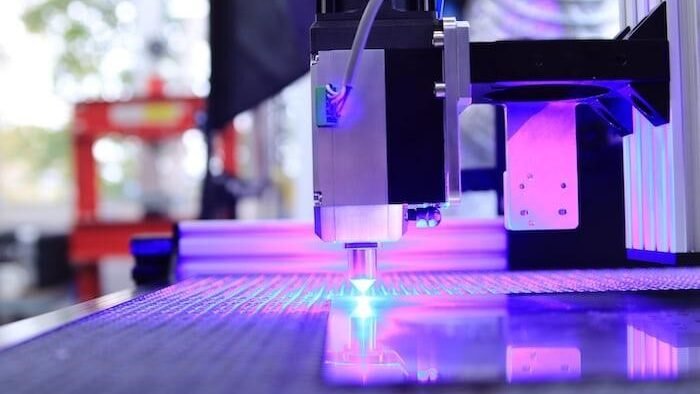

Picture caption: A CNC machine uses machine learning to make 3D prints.)

Various complex elements are made and assembled using a range of manual and automated processes to form the injection mold or mold tool to guarantee a reliable and repeatable injection molding process. These components are shaped to tight tolerances using specialist machinery, including CNC machining and EDM (electrical discharge machining), which significantly adds to the cost.

3. Machinery cost

Special molding machinery is used. A machine costs $10000 (small) or less for low-volume injection molding and $200,000 (big) for high-volume injection molding, depending on its size and automation. Medium-level molding can be done on $50,000-plus machines. Take into account the following injection molding machine types and their costs:

- Injection molding machines employ a hydraulic pump to control the machine. They’re durable, consistent, and cheap to buy. Energy-intensive and imprecise.

- Electric injection molding machines employ electro-servo motors to control and mold. Their accuracy, energy efficiency, operating and maintenance expenses, and ease of use are all advantages. They cost a lot and need regular maintenance.

- Injection molding machines that combine both are called hybrids. Energy efficiency, precision, and reproducibility define them. They have a significant initial investment and require heavy maintenance due to hydraulic pumps and electric motors.

Businesses outsource injection molding to service providers like Kuixing Electronics instead of buying their machines. The service provider’s service cost replaces the machine’s high cost.

4. Labour Costs

You have to assess the cost of labor too. It requires a lot of time, effort, and expertise to design, build, and assemble injection molds properly. The designers and builders of injection molds are experts in their field and command a premium price. Skimping on this can lead to more expensive consequences down the road.

Why the Price Is Worth It

Although injection molding is an expensive process, it is worth the cost. The process requires most funds in the beginning but it’s just a one-time investment. After the molds are made the cost of production reduces dramatically.

Although injection molding is an expensive process, it is worth the cost. The process requires most funds in the beginning but it’s just a one-time investment. After the molds are made the cost of production reduces dramatically.

Tips to Reduce the Cost

1. Choose the right country:

Plastic molding is way cheaper in some counties than in others. In China, where Kuixing Electronics is located, the cost of production is 20-30% cheaper than in the US. So, you must look at international companies while making your project budget.

2. Optimize your design:

Optimization of the design means making sure it’s efficient and uses the least amount of material while maintaining quality. You need to simplify complex designs and reduce thickness where possible.

3. Select inexpensive materials:

Select inexpensive materials that meet the specified criteria. Reusing or cycling recycled materials might also help you save money.

4. Tooling:

Tools such as multi-cavity molds enhance productivity while decreasing cost per part. You can look into the tooling variety and select the one that resonates well with your budget.

5. Collaborate with Suppliers:

Working closely with suppliers to negotiate better pricing on raw materials, tooling, and other services can help you lower your expenditure.

6. Quality Control:

Quality inspections to reduce defects, rework, and scrap, can drastically reduce waste costs, optimizing your budget.

Conclusion

Injection molding can be expensive due to various factors. The initial tooling, designing, and manufacturing of the molds, are significantly expensive. Material costs, especially for high-performance or specialized polymers, add up. Moreover, Complex designs or intricate features that demand precision tooling and longer production times, increase the costs. However, injection molding remains valuable due to its high production speed, scalability, and precision. It offers tight tolerances, minimal material waste, and consistent quality, making it a preferred choice for mass production of intricate parts across industries, offsetting its initial expenses over time. Additionally, by following the tips listed above you can even reduce the expected price.

Plastic injection molding might demand some initial investment, but the results of this process justify the cost.

External link:

1-https:// www.rapiddirect.com/blog/injection-molding-costs/

2 Responses